Guest Post by Geary Sikich (first posted on CERM ® RISK INSIGHTS – reposted here with permission)

Overview

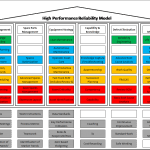

The ability to effectively respond to and manage the consequences of an event in a timely manner is essential to ensure an organization’s survivability in today’s fast paced business environment. With the emergence of new threats, such as cyber-terrorism and bio-terrorism; and the increasing exposure of companies to traditional threats such as, fraud, systems failure, fire, explosions, spills, natural disasters, etc. an “integrated” approach to Business Continuity Planning is essential. [Read more…]

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.