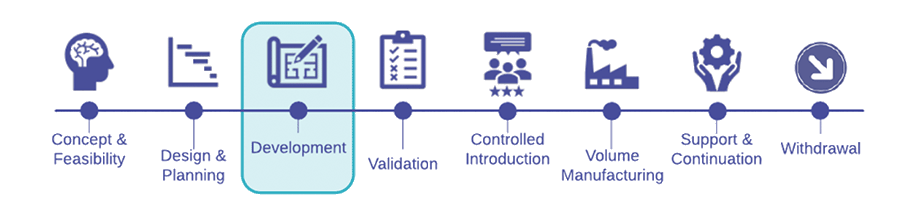

Yes, reliability testing can be done in parallel with design validation (DV). This approach has both advantages and disadvantages, which are important to consider in the context of product development and testing. Pros of conducting reliability testing in parallel with design validation include time efficiency. Conducting reliability testing in parallel with (DV) can significantly reduce the overall time required for product development. By overlapping these processes, you can identify and address potential issues earlier, which can accelerate the time to market. Early detection of issues running reliability tests alongside (DV) allows for the early detection of design flaws or weaknesses. This can lead to quicker iterations and improvements, enhancing the overall quality and robustness.

[Read more…]

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.