(and Why It Matters)

In the world of reliability engineering, few tools are as powerful – or as misunderstood – as Weibull analysis. It is a statistical tool, which can turn people ‘off’ straight away, as we can immediately leap to a list of equations and tables of numbers that we need to memorize and embrace. But Weibull analysis is different. You actually don’t need equations.

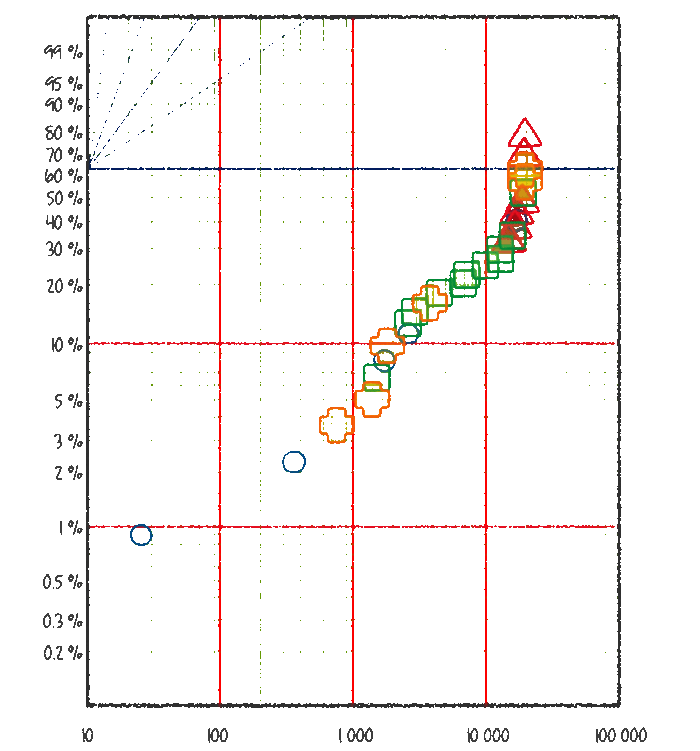

Check out the chart below, which is called a ‘Weibull plot.’ The different shapes and colours representing the failures of different components can tell us so many things without having to evaluate a single equation.

For example, the curves and bend on the chart above shows that for a mining truck engine assembly, a switching valve is failing due to installation issues or defects (which a quick review of prescribed steps can identify), another component is failing from randomly occurring external stresses (that additional caging and protection could eliminate), and that the component that ‘limits’ the life of the engine is a small scavenge pump that is wearing out (which could be simply and cheaply replaced with a more robust pump).

You can find all this out if you just need to know what to look for. And now you know some simple steps you can undertake to dramatically (and cheaply) improve reliability.

But if you do want to take the next step and start dealing with numbers, you can predict failure rates, optimize maintenance schedules, and make data-driven decisions, even with limited failure data. Yet, despite its versatility, many professionals lack formal training in Weibull analysis, limiting their ability to fully leverage its benefits.

Mastering Weibull analysis isn’t just a technical or professional development milestone – it’s a strategic advantage. It is much easier to do than people think, but it is also easy for people to learn a couple of elements of Weibull analysis and mistakenly think they know everything. So it is very important to be qualified when it comes to Weibull analysis.

Why Weibull Analysis Matters

Weibull analysis is a cornerstone of reliability engineering. The reason is that the underlying ‘Weibull distribution,’ upon which it is based, models particular ways things fail by understanding how long it takes for the last residual part of a component to ‘break’ when it is under stress. So, regardless of whether the component fails due to fatigue, wear, corrosion, or even infant mortality, the Weibull distribution does a very good job of modelling how each happens.

This means that Weibull analysis can offer insights into product lifecycles, failure modes, and maintenance needs. Unlike other statistical methods, Weibull analysis can handle small data sets and adapt to the various ways things fail, making it invaluable for early-stage product assessments and ongoing reliability monitoring.

But let’s get into a few more key benefits of Weibull analysis:

Preventive Maintenance. Weibull analysis can help us find the first signs of a product wearing out, helping us work out how often to conduct preventive maintenance (PM) correctly. If we make our PM intervals too short, we waste time and introduce lots of maintenance-induced failures. If our intervals are too long, the failures we are trying to prevent occur anyway. This means we can reduce downtime and maintenance costs in an informed way.

Warranty Optimization. You want to offer a long warranty period to attract more customers and dominate your competitors. But you don’t want your warranty period to be so long that you are paying for so many failures that you lose your profit margin. Weibull analysis can help you work out how long your warranty period should be.

Failure Mode Identification. Remember those different components failing on our mining truck engine in that ‘Weibull plot’ we talked about earlier? Understanding how they fail is very important for working out what to do about them. Weibull analysis shows you which products are wearing in or experiencing infant mortality. These are the ones where you need to look for defects or pre-existing damage before they are used. Those that wear out are the ones that can be targeted for PM, predictive maintenance, or even upgraded to improve the useful life of the system.

Resource Allocation. Weibull analysis helps you work out which components to address and what to do. This helps you make informed decisions about where to focus reliability efforts and investments (in other words … you don’t waste time furiously fixing the wrong problem).

By understanding and applying Weibull analysis, engineers can transform reactive maintenance strategies into proactive reliability programs.

The Value of becoming ‘qualified’ to do Weibull analysis

There is a lot of information out there teaching us how to change the sealing valve in a toilet, planting flowers in your garden, learning a new language, and so on. There is a fair bit of free (or at least, widely available) Weibull analysis content. But while self-study can provide a basic understanding of Weibull analysis, formal training and certification offer several distinct advantages.

First, there is the Structured Learning. Formal courses that offer qualification and certification programs provide a comprehensive curriculum that covers both fundamental concepts and advanced applications. When you try to learn by yourself, you don’t know which bits are the most important to learn, which bits that people say you need to learn (but don’t need to), and perhaps most importantly, when you have learned all that you actually need for your specific reliability engineering requirements.

Then there is the Hands-On Experience. Many courses include practical exercises using industry-standard software, ensuring you can apply what you’ve learned. But even then, you need to have an understanding of which software works for you (and not). When you try to learn by yourself, you might come across software promotional videos masquerading as lessons.

Gaining qualifications and certification gives you Credibility. These demonstrate expertise to employers, clients, and peers, enhancing your professional reputation. One of the biggest problems reliability engineers have is being believed. Showing your certifications and qualifications really help.

Career Advancement is something that being a certified ‘Weibull analysis master’ can really help. Certified professionals often have better job prospects and opportunities for advancement in reliability engineering roles. In any industry where achieving reliability quickly and cheaply is important (which would be every industry), certification in Weibull analysis signals a commitment to excellence.

Choosing the Right Weibull Analysis Certification Program

So let’s say that you have chosen to become certified in ‘Weibull analysis’ and start looking for a program. Every course or certification provider will tell you that their program is the best. So consider the following factors:

Understanding the problems you want to solve. While Weibull analysis can be helpful in a very generic sense, understanding the problem (or types of problems) you want to be able to use Weibull analysis to help you solve is very important. If you can’t see how Weibull analysis can help solve your problem, then you are probably looking at the wrong course!

Curriculum Depth. Ensure the course covers both basic and advanced topics relevant to your role. If the course outline focuses on mastering statistical concepts like maximum likelihood estimation, the Fisher information matrix approach to confidence, and regression on Y versus X – without explaining how mastering these things will help you actually make better decisions – find another course!

Instructor Expertise. Look for programs taught by experienced professionals with practical industry knowledge. You don’t want instructors who have spent their entire careers in academia. You also don’t want instructors who haven’t spent any time mastering their own statistical analysis expertise.

Software (pros and cons). Many Weibull Analysis software packages are extremely expensive. Some courses actually focus on teaching students how to use their software, which is not the same as learning how to do Weibull analysis. Once you have completed their course, you are essentially locked into paying for their software forever. Other organizations can make the distinction between the two. Some programs teach you how to become proficient in Weibull analysis without software … meaning you can pick and choose your approach to off-the-shelf tools afterwards.

Where to now?

Become qualified or certified in Weibull analysis is more than a professional milestone – it’s a strategic investment in your career and your organization’s success. By mastering this powerful tool, you can lead initiatives that reduce failures, optimize maintenance, and improve product reliability.

But Weibull analysis is just a tool. It isn’t mandated, nor should it be. So work out what you want to achieve personally and professionally before you embark on a particular program. If reliability engineering isn’t making you money, then you are doing it wrong.

Reliability engineering happens at the point of decision. We went through some potential decisions above in our real-world example. Should we upgrade our small scavenge pump to improve engine reliability? The Weibull plot gives us the answer. What do we need focus on to improve a switching valve’s reliability? A Weibull plot can show if you need to look at installation. What should our PM interval be? Again, a Weibull plot can show you what this should be.

So if these sorts of decisions resonate with you, start learning how to do Weibull analysis. Use the criteria above to find the right approach for you. And finally, work out how to explain to yourself or your boss how Weibull analysis can help you make better decisions that help you save time and money.

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.

Leave a Reply