A proximity switch is the common name for a range of detectors that generate an electrical signal when a physical mass cuts through their sensor field. Upon detection of an object, the electrical signal is sent to a controlling device and is used to monitor and control the operation of the equipment.

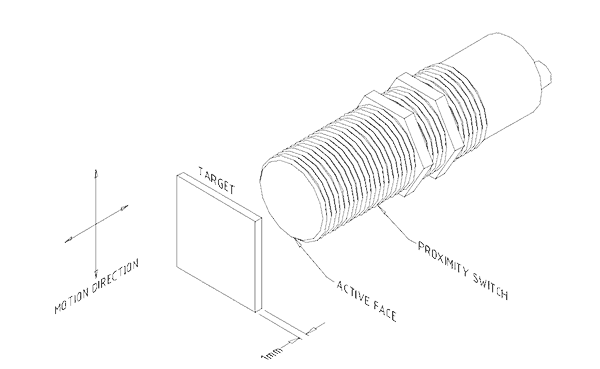

The sensors can be based on optical techniques like cutting a laser beam or detecting a bar code. They can use magnetic field techniques where the body mass changes the magnetic field characteristics. They can be a capacitive device where the detected body alters the sensor’s electrical characteristics. They can be a mechanical switch that closes when hit by a body. They can use ultrasonic sound and detect its reflection. Figure 1 shows an inductive proximity switch detecting a target.

You would use a proximity switch to confirm whether an item is where it should be. For example if you want to detect the position of a valve you can mount proximity switches to detect the location of a flat bar attached to the valve stem. Two switches, at the fully opened and fully closed positions, tell you the position of the valve. If you include a timer in the sensing circuit you can detect the rotation of a shaft. By mounting a tag protruding from the rotating shaft and setting the detector distance to note the passage of the tag, a signal is generated each time it cuts the sensor’s beam. If the sensor does not detect the tag in a certain period of time it could be assumed the shaft has stopped and an alarm can be raised.

Selecting the right sensor for the job involves more than deciding the appropriate technology. Most times sensors fail because of local conditions – they need to be kept clean, cool and dry. Will the weather and sunlight damage the housing? Will the sensor pick-up heat from the process and get cooked? Are there furtive chemical vapours in its vicinity that will destroy its components? Are the operators going to hose it down? Are they going to use steam on it? Is it a dust, dirty, oily, never cleaned location? Does it have to take accidental impact? Is the forklift driver going to run his load into it? Will someone step on it to get somewhere else? These are the sorts of things that destroy sensors.

Mike Sondalini – Maintenance Engineer

We (Accendo Reliability) published this article with the kind permission of Feed Forward Publishing, a subsidiary of BIN95.com

Web: trade-school.education

E-mail: info@trade-school.education

If you found this interesting you may like the ebook Process Control Essentials.

Leave a Reply