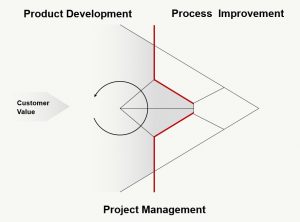

Change is an inevitable part of every industry, and maintenance is no exception. Whether it’s the introduction of new technologies, processes, or leadership, how an organization handles change can significantly impact its operational efficiency and overall success. However, when it comes to maintenance, true change management goes beyond simply implementing new systems—it’s about transforming the culture, mindset, and approach of the entire organization to ensure lasting improvement.

[Read more…]

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.