Make Use of a Risk Cost Calculator and Risk Matrix

Risk is probabilistic—a risk event may happen or it may not. The human mind struggles to understand probability until you make a picture.

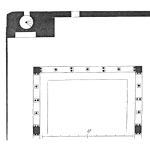

Here is a simple visual management tool to let you see the impact of changing risk. Combine it with a risk cost calculator and you have an effective way to see how your risk changes with risk management plans and risk abatements

We are blind to risk. Most of us have to suffer a risk event before we know we are in one. We first experience pain and then we realise that we need to stop doing what is causing the pain.

[Read more…]

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.