Mercedes used to be known for their outstanding reliability. They were the benchmark for 80 years ,no exageration. The new CLA250 model which is their base model has a reliability that is 140% less than the average rated car. What??? [Read more…]

Your Reliability Engineering Professional Development Site

Mercedes used to be known for their outstanding reliability. They were the benchmark for 80 years ,no exageration. The new CLA250 model which is their base model has a reliability that is 140% less than the average rated car. What??? [Read more…]

by James Kovacevic Leave a Comment

Planning and Scheduling is the core of any reliability program. It is part of Work Control process which is described as the execution of a work order from start to end, and setting the right expectations to everyone involved. The role can be viewed separately or as a hybrid, depending on the maturity of the organization and the complexity of the process.

ᐅ Play Episode

by Greg Hutchins Leave a Comment

Guest Post by Geary Sikich (first posted on CERM ® RISK INSIGHTS – reposted here with permission)

The Law Dictionary defines Collateral Risk as:

The RISK of loss arising from errors in the nature, quantity, pricing, or characteristics of COLLATERAL securing a transaction with CREDIT RISK. Institutions that actively accept and deliver collateral and are unable to manage the process accurately are susceptible to loss. A subcategory of PROCESS RISK. [Read more…]

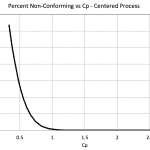

In the article Process Capability I – Overview and Indices, the main process performance indices were defined. In the article Process Capability Analysis II – Estimating Percent Defective, ways to calculate the percent defective were introduced.

In this article, the mathematical connection between the Cp index and percent defectives is made.

by Fred Schenkelberg 1 Comment

In most organizations being a reliability engineer is a lonely position. I like to think we’re so effective that one or just a small team is all any an organization needs.

As with any engineering position, we have specialized training and skills. We view the world and problems just a little differently than others. Then we use statistics, which tends to future isolate us from our peers.

For over 50 years there have been professional societies focused on supporting the professional education of reliability engineers. For nearly as long there have been trade journals and newsletters. Longer for technical journals and other scientific and engineering organizations and journals. [Read more…]

Those who know me well know I am a voracious reader. From newspapers and magazines to business related books and novels it’s a rare site to find me without my Kindle or some type of printed reading material. Lately I have noticed a number of articles on the reasons why your best employees are leaving your business and I have to say I saw this problem trend coming more than a decade ago. [Read more…]

by Doug Plucknette Leave a Comment

Having visited hundreds of manufacturing plants in the last 17 years, someone recently asked me if there were any traits the most reliable plants all had in common. I have listed below the top 6 signs of a reliable plant. [Read more…]

by Greg Hutchins Leave a Comment

Guest Post by Geary Sikich (first posted on CERM ® RISK INSIGHTS – reposted here with permission)

What is risk? Think about it before you leap to answer. Do we really know and understand risk? Some facts to consider:

Risk management requires that you constantly monitor recognized risks and continue to scan for new risks. This process cannot be accomplished with a ‘one and done’ mindset. Risk needs to be looked at in three dimensions and perhaps even four dimensions to begin to understand the “touchpoints” and aggregation of risk, potential to cascade, conflate and/or come to a confluence. [Read more…]

by Doug Plucknette Leave a Comment

I’ve been told that humor, especially New York sarcasm doesn’t go over too well on LinkedIn. That as a regular contributor of articles, blog postings and hopefully useful updates one should try avoid attempting to use humor as a teaching tool.

Well those who know me well know I also don’t always follow the advice of those who somehow believe we all learn the same way, think the same way and therefore do things the same way. I’m a guy who believes that while common sense might not be that common, when you explain why something makes sense most of the audience will get it. For the others who still don’t understand I of course bring data.

by Fred Schenkelberg Leave a Comment

Some products and systems are just dangerous, inherently. Understanding inherent safety-related risks permits a team to design out or mitigate those risks. Hazard analysis is the systematic process of identifying and controlling safety risks.

[Read more…]

A few months back, I wrote a blog resulting from a conversation I had with a group of Maintenance Technicians who were attending the International Maintenance Conference (IMC) in 2011. While the group was enjoying the conference and learning some new things, the general consensus was that they felt they would not be able to apply the tools and techniques they were learning because “management will say they support reliability, but when it comes right down to it, talk is cheap.”

by Greg Hutchins Leave a Comment

Guest Post by Greg Carroll (first posted on CERM ® RISK INSIGHTS – reposted here with permission)

In my 2013 book Mastering 21st Century Enterprise Risk Management: Firing Dated Practices | The Best Practice of ERM | Implementation Secrets I quipped “just as the Wild West of the 1890’s had disappeared without trace by the Roaring 1920s, so too will the business world of the 1990s, be long forgotten by the 2020s”. Just 5 years on and not only has the world changed emphatically but the rate of change is accelerating. [Read more…]

by Greg Hutchins Leave a Comment

Guest Post by Geary Sikich (first posted on CERM ® RISK INSIGHTS – reposted here with permission)

In the risk-neutral world, all business and government continuity planning would be risk-balanced. However, in reality, risks, threats, hazards and their consequences change depending on an organizations exposure, sensitivities to impact and other factors. For instance, a natural disaster, can occur without much warning and can have direct and indirect impact on an organization. Complicating the Business Continuity Planners life is a simple fact, events have unforeseen consequences that can rarely be planned for.

A topic that often comes up lately is high turnover, especially the perception that this is common and desirable among millennials. Born in the mid eighties, I am right on the cusp between millennial and Generation X, and I am one of the aforementioned employees with a high turnover history. A specialized Reliability Engineer with nearly ten years of work experience, I have rarely stayed with a company much over two years. I never intended to be a person who moved between companies so regularly, it just kind of happened. [Read more…]

by Carl S. Carlson Leave a Comment

Is action always required on high-severity issues? What if severity is high (9 or 10 on a severity scale of 1 to 10), and the occurrence and detection rankings are both low? Is action still required? This problem, as well as a challenging problem involving fail-safe strategies, are the subject of this problem-solution article.

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.