A Practical SPC Method for High-Capability Processes

By Ray Harkins and Michael J. Vella

Manufacturing professionals who regularly apply Statistical Process Control (SPC) methods, such as X̄ and R charts, know the power of SPC to maintain control of both quality and cost. The standard practice emphasizes attention to variation, with operators trained to take corrective action whenever a process signals an out-of-control condition. Typically, this means adjusting a process input, verifying the correction, and resuming production.

However, not every out-of-control signal requires intervention, especially in processes where inherent variation is extremely small and product quality is consistently high. In some cases, such as tooling wear or small material variations, process center shifts may occur outside of the operator’s ability to correct. Responding to these shifts with standard SPC rules can lead to overcorrection, lost productivity, and increased variation.

The Fixed Capability Technique offers an alternative. It allows production to continue under statistical control while tolerating predictable, non-correctable shifts in the process center—provided the process is otherwise capable and stable. This technique is especially useful in high-capability environments where traditional control chart reactions may cause more harm than good.

When to Apply the Fixed Capability Technique

The Fixed Capability Technique is appropriate only when certain conditions are met. These include:

- Adequate Gage Capability: The measurement system must demonstrate acceptable accuracy, repeatability, and reproducibility—typically with less than 10% gage error.

- Short-Term Stability: The process must show stable variation over short intervals, confirmed through control charting (e.g., X̄ and R charts) or a frequency distribution analysis.

- Demonstrated High Capability: The process must have a short-term Cpk of at least 2.0, meaning the piece-to-piece variation is minimal and well within specification limits.

- Uncontrollable Center Shifts: There must be a known and understood input—such as non-adjustable tooling or minor raw material variation—that causes shifts in the process center over time but cannot be corrected by the operator.

- Organizational Commitment to Quality: Teams must be engaged in continuous improvement efforts, including training, tooling optimization, and method control.

- Cross-Functional Support: Key stakeholders—such as Supplier Quality Assurance, Product Engineering, and downstream customers—must understand and support the approach.

When these conditions are in place, the Fixed Capability Technique provides a legitimate alternative to standard SPC methods, preventing unnecessary disruptions while maintaining product quality.

Methodology

The method modifies control limits to ensure a minimum process capability—e.g., Ppk ≥ 2—is maintained, even when the process center drifts slightly. Here’s a general outline:

- Establish Measurement Integrity: Use fixtured, digital read-out gages with at least 20 increments across the specification spread.

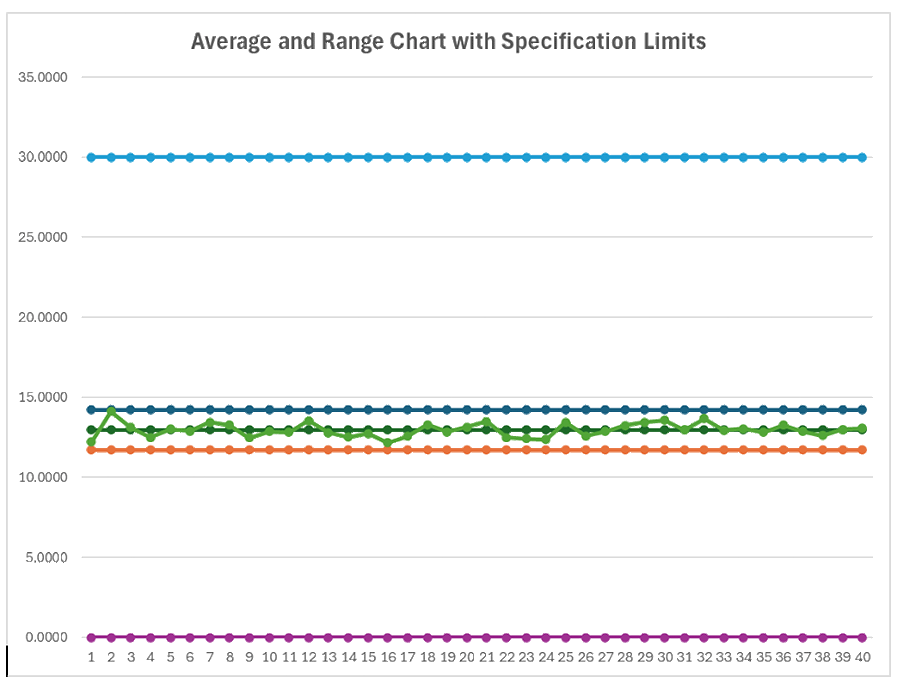

- Confirm Baseline Capability: Perform a process capability study using a rational subgrouping strategy (e.g., 5 samples per subgroup, 50 subgroups), as described in Grant and Leavenworth’s Statistical Quality Control.

- Calculate Standard Deviation and Control Limits:

- Estimate the process standard deviation:

- Calculate conventional control limits centered at the specification target using constants such as A₂ for the X̄ chart.

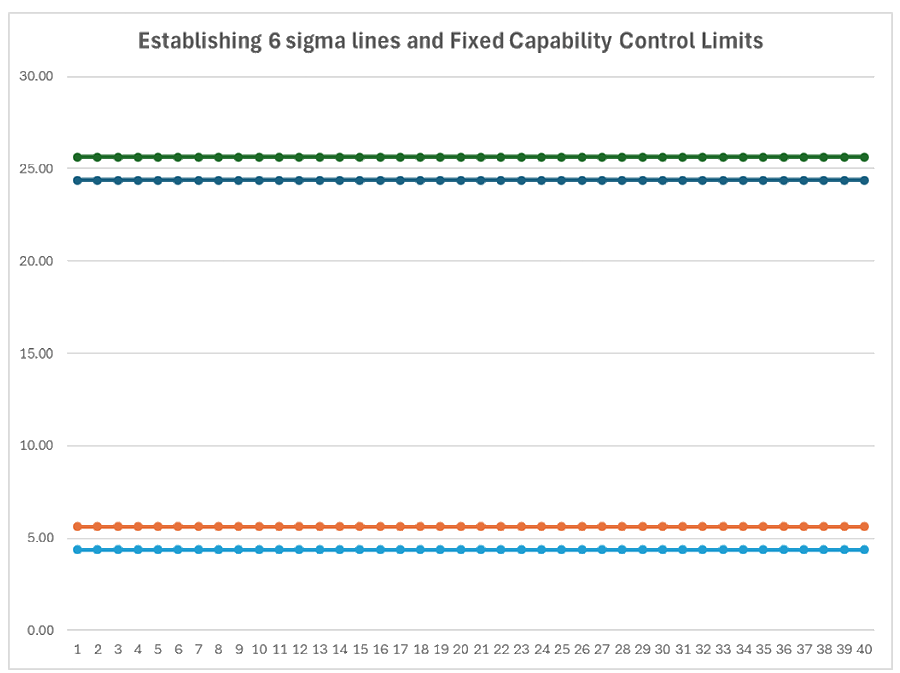

- Set Fixed Capability Limits:

- Determine how far the process center can shift and still achieve a specified minimum capability (e.g., Ppk = 2).

- Use this distance to define outer control limits—your Fixed Capability Control Limits.

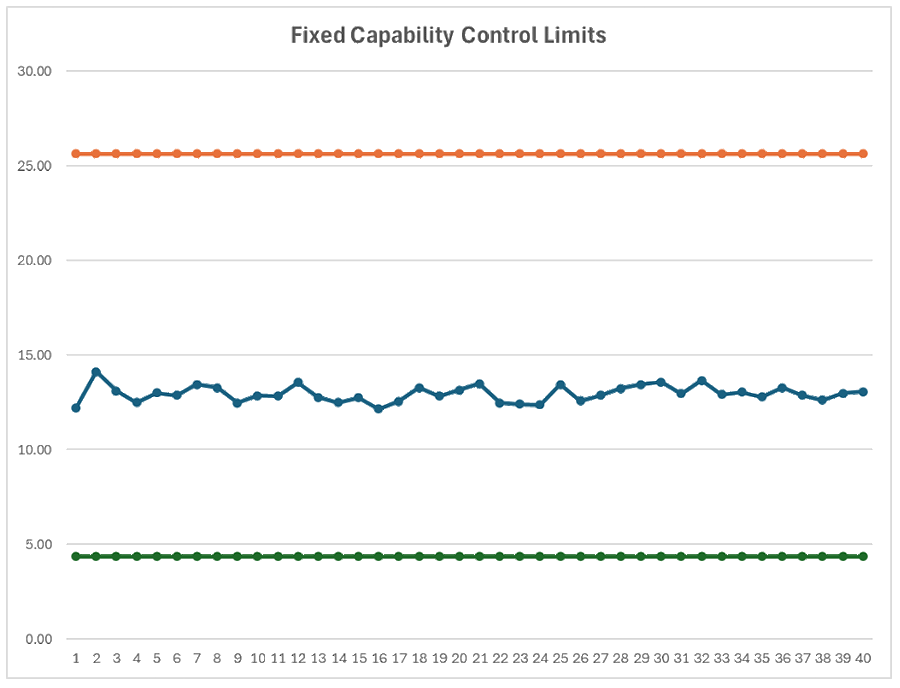

- Allow the process to operate within these bounds without adjustment, unless the average or median crosses these control limits.

A Real-World Example

In the mid-1980s, Ford Motor Company launched the Taurus/Sable—a highly successful mid-size vehicle platform. The vehicle’s transmission tubes were precision press-fit components sourced from a trusted supplier, while hole placement was controlled tightly at Ford’s Livonia, Michigan plant.

To meet tight tolerance requirements, the supplier used a two-step process: end forming and sizing. Over time, the sizing dies—made of hardened steel—would pick up material during production, leaving scratches on the part and requiring polishing. While polishing removed surface defects, it also slightly enlarged the die, leading to a slow, progressive shift in the process center.

The short-term variation remained small, and the process consistently produced within specifications. Yet, conventional SPC rules flagged the process as out of control due to the shift in the center (e.g., 7 points in a row on one side of the average). Operators were forced to shut down and replace otherwise functional tooling.

Using the Fixed Capability Technique, the team at Ford—with support from Supplier Quality Assurance—was able to define acceptable process shifts while preserving high capability (Ppk ≥ 2). The technique allowed continued production, reduced unnecessary tooling changes, and upheld both product quality and cost-effectiveness.

Pitfalls of Misuse

Like any tool, the Fixed Capability Technique can be misapplied. Its successful use depends on honest evaluation of the process and a disciplined commitment to quality. Here are some common pitfalls:

- Using it to avoid root cause analysis: The method should not serve as a shortcut to sidestep real problems. If process center shifts stem from special causes that could be corrected, those should be addressed directly.

- Applying it to marginal processes: The technique assumes an already high-capability process. Applying it to borderline or unstable processes can mask quality issues and increase customer risk.

- Inadequate communication: Because this approach deviates from standard SPC rules, cross-functional teams—including auditors and downstream users—must be fully briefed and aligned.

- Neglecting long-term monitoring: Even when Fixed Capability Control Limits are in use, regular review of process trends and tool wear is essential to avoid degradation over time.

In short, the Fixed Capability Technique is not a license to relax standards—it’s a disciplined alternative tailored for specific high-capability scenarios.

The Fixed Capability Technique provides a statistically defensible way to maintain control in highly capable processes subject to predictable and benign shifts in the process center. By defining wider control limits based on desired minimum capability, manufacturers can avoid unnecessary process interruptions, reduce cost, and still maintain high-quality output.

In Ford’s transmission tube manufacturing case, this approach proved to be a practical solution that supported both continuous improvement and operational efficiency. For engineers and quality professionals facing similar constraints, the Fixed Capability Technique offers a powerful, if specialized, addition to the SPC toolkit.

References

- Grant, E. L., & Leavenworth, R. S. (1964). Statistical Quality Control (5th ed.). McGraw-Hill.

- Ford Motor Company. (1984). Continuing Process Control and Process Capability, P.T. Jessup, Contributor.

Authors’ Biographies

Ray Harkins is the General Manager of Lexington Technologies in Lexington, North Carolina. He earned his Master of Science from Rochester Institute of Technology and his Master of Business Administration from Youngstown State University. He also teaches manufacturing and business-related skills such as Quality Engineering Statistics, Reliability Engineering Statistics, Failure Modes and Effects Analysis (FMEA), and Root Cause Analysis and the 8D Corrective Action Process through the online learning platform, Udemy.

Mike Vella served as Senior VP Operations at the Suter Company, an employee-owned food producer located in Sycamore, Illinois for 12 years. Prior to joining Suter, Mike was the Vice President and General Manager of TI Automotive’s Brake and Fuel Group in North America. He is a Fellow with the American Society of Quality and an instructor with the Manufacturing Academy, developing training resources focused on quality, problem solving, and statistical analysis.

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.

Leave a Reply