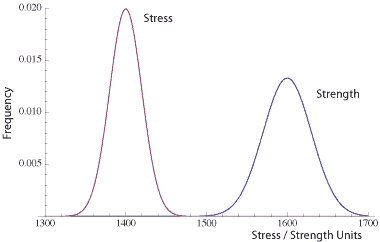

Product Reliability Design

One way to capture and disseminate reliability engineering related information and advice is through internal documents. This of course only works if they are both useful and used.

Focus on gathering and providing essential and meaningful information that will improve the reliability of your product. Another element that makes these design guidelines valuable is if they save time. Engineers love to save time. [Read more…]

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.