Article by Wayne Miller

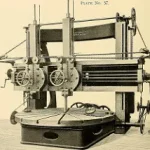

Many companies, especially for high-complexity products such as energy storage and robotics, are moving away from outsourced manufacturing to establish their own internal operations. In fact, Kearney’s 10th Annual Reshoring Index finds that reshoring has substantially increased during the past decade.

This paradigm shift, driven by the need for closer design and production integration, poses opportunities and challenges. This article delves into the essential steps and considerations to set up an effective internal manufacturing facility tailored for the hardware-based product industry.

[Read more…]

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.