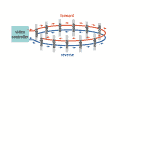

In the article Calculating Network Reliability the lack of published analytical solution for dual-ring network reliability was highlighted. This article provides a neat solution and further challenges readers to offer their proof or prior publication reference. The solution and the author’s general proof will be presented at RAMS 2020.

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.