Understanding the risks allow effective mitigation plans to be put in place

Where is your biggest risk to the site? If you can’t answer that, than your maintenance program is most likely not adequate. As previously discussed, an effective maintenance program must align with business and its needs. A criticality analysis allows the site to understand where there are risks that must be managed.

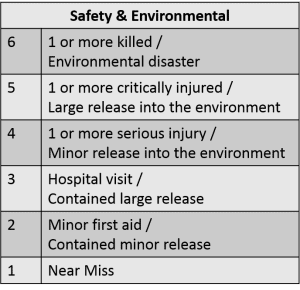

A criticality analysis is a systematic approach to evaluating potential risks, therefore consequences that can impact the business. The criticality analysis has defined criteria that outlines the potential consequences so that they can be evaluated, categorized and prioritized. Using the defined criteria for each major area of risk ensure all equipment is vaulted with emotion removed as much as possible. The criteria can be defined to the level of detail required by the business, but 5 to 6 levels for each category is typically adequate for most businesses. The criteria should be stated in such a way that there is little room to interrupt differently (see figure 1). The criteria should be define for Environmental, Health & Safety, Operational, and depending on the industry, Customers can be included.

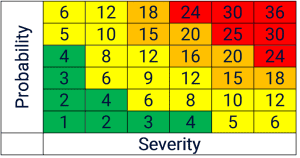

There are often many ways to conduct a criticality analysis. Some approaches use a 6×6 grid (see figure 2) in which the probability is plotted against the severity and the result is a risk priority number (RPN). In this instance the severity is the worst case situation, regardless if it is an operational risk, environment, or health & safety. The same goes for the probability.

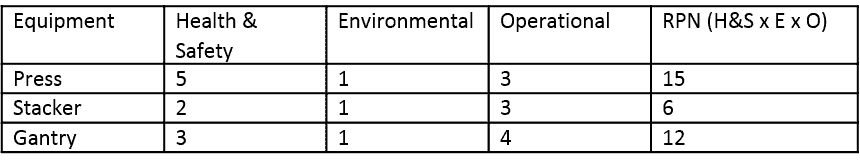

In another approach, all of the major consequence categories are evaluated as independent severities and the probability of the worst case failure is determined (see figure 3). This ensures that potentially consequences are evaluated. During this type of analysis, each consequence’s risk number is either added or multiplied against each other, resulting in the RPN.

Which approach to use is dependent upon the size and complexity of the business. If the business is complex and has many external stakeholders, than the criticality analysis will have to reflect that. If the business is a simple manufacturing operation, than the 6×6 grid is more than adequate.

Regardless which approach that is, the ranking of equipment criticality will typically fall into a bell curve shape, with most equipment presenting some type of risk to the site, with a few at the high risk end and the no risk end. Some industries may differ, and that is ok, as long as all of the equipment was evaluated using the defined criteria.

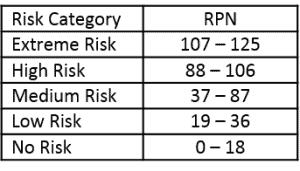

The equipment should be grouped into categories based on the RPN. There typically are 5-6 categories of equipment (see figure xx). They may range from no risk, to extreme risk. This step is optional, but can be used to further leverage the power of the criticality analysis which will be covered in a different post.

When evaluating the criticality for each piece of equipment, it is best to use a cross functional group which includes, quality, operations, maintenance, health & safety and any other significant stakeholder in the plant. This ensures every group has input into the criticality rating of the equipment and is less likely to dispute any decision based on the criticality rating.

A few points to keep in mind when conducting a criticality analysis

- Break it down to the significant piece of equipment, not the individual component level.

- If evaluating a process, no equipment contained within it should have a higher criticality rating.

- The analysis is large undertaking, so break it down into a series of sessions, with each session focusing on a specific area of the operation.

- Record the criticality rating in the equipment records for use in planning, scheduling and other activities.

With the criticality defined for each piece of equipment, the maintenance department is now in tune with the business needs. Maintenance can now make data driven decisions, based on the agreement of the stakeholders and not on emotion. This is the one of the first steps to building an effective maintenance strategy.

Does your operation have an up to date criticality analysis? If not, when was the last time one was completed? When will you be conducting one?

Remember, to find success, you must first solve the problem, then achieve the implementation of the solution, and finally sustain winning results.

I’m James Kovacevic

HP RELIABILITY

Solve, Achieve, Sustain

I am rely interesting about your subject