Being an UpKeep Ambassador Securing Leadership Buy In and Beyond with Sanya Mathura

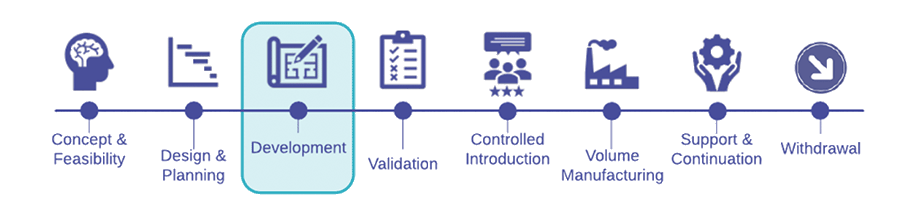

In this episode, we explore key strategies for implementing a Computerized Maintenance Management System (CMMS), with a focus on gaining leadership support and maximizing efficiency. Sanya Mathura, a returning CMMSradio guest and bona-fide expert, provides actionable advice on documenting operational issues, quantifying costs, and linking CMMS benefits to business objectives. The importance of financial justification and preparation for organizational change and, as an UpKeep Ambassador, Sanya discusses how leveraging UpKeep can enhance your CMMS experience and drive better maintenance results.

- Document Operational Issues: Track and document issues such as equipment failures and part shortages to build a compelling case for a CMMS.

- Quantify Costs: Calculate the costs associated with inefficiencies, like the time spent searching for parts, to highlight the financial impact of not having a CMMS.

- Present Financial Savings: Show potential savings from using a CMMS by comparing current costs with the projected improvements in efficiency and productivity.

- Link to Business Goals: Align CMMS benefits with overall business objectives, such as increasing efficiency, reducing downtime, and enhancing asset management.

- Use Industry Benchmarks: Compare your organization’s performance with industry standards to identify areas where a CMMS can offer significant improvements.

- Seek Leadership Buy-In: Use documented data and financial analysis to make a persuasive case to leadership about the value and return on investment of a CMMS.

- Leverage UpKeep Ambassadors: Connect with UpKeep ambassadors, like Sanya or Greg, to gain insights and support for successful implementation and utilization of your CMMS.

- Prepare for Change: Anticipate and address potential resistance to change by demonstrating how a CMMS aligns with organizational goals and enhances overall reliability and efficiency.

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.