What’s Wrong with MTBF

Abstract

Carl and Fred discussing the pitfalls of using Mean Time Between Failures (MTBF) as a metric for identifying reliability requirements.

ᐅ Play Episode

Your Reliability Engineering Professional Development Site

by Carl S. Carlson Leave a Comment

Carl and Fred discussing the pitfalls of using Mean Time Between Failures (MTBF) as a metric for identifying reliability requirements.

ᐅ Play Episode

by Christopher Jackson 3 Comments

Chris and Fred discuss how management teams across many institutions continue to misuse the MTBF while believing they are fluent in the field of reliability (when they clearly aren’t)!

ᐅ Play Episode

Adam and Chris Stapelmann discussing metrics for reliability software.

ᐅ Play Episode

A Series of Unfortunate MTBF Assumptions

A Series of Unfortunate MTBF AssumptionsThe calculation of MTBF results in a larger number if we make a series of MTBF assumptions. We just need more time in the operating hours and fewer failures in the count of failures.

While we really want to understand the reliability performance of field units, we often make a series of small assumptions that impact the accuracy of MTBF estimates.

Here are just a few of these MTBF assumptions that I’ve seen and in some cases nearly all of them with one team. Reliability data has useful information is we gather and treat it well. [Read more…]

by Andre Kleyner Leave a Comment

Andre and Fred discussing why we do not like using MTBF.

ᐅ Play Episode

by Adam Bahret Leave a Comment

Mean Time Between Failure (MTBF) is one of the most well know reliability metrics.

But to anyone who works with reliability, it seems like it was developed by some evil anti-reliability mastermind to undermine the possibility of connecting reliability to anything or anyone.

Mean Time Between Failure means what?

This is the process of understanding everyone goes through as they are introduced to MTBF, formally or informally. [Read more…]

by Fred Schenkelberg 1 Comment

You have carefully crafted a detailed reliability goal including function, environment, probability, and duration, plus apportioned it to critical supplied subsystems and components. Your vendor decides to use MTBF instead.

What can you do? What should you do?

by Fred Schenkelberg Leave a Comment

You have carefully crafted a detailed reliability goal including function, environment, probability, and duration, plus apportioned it to critical supplied subsystems and components. Your vendor decides to use MTBF instead.

What can you do? What should you do?

Mean Time Between Failure or MTBF is almost universally recognized in maintenance, reliability, and asset management.

Why is that? And does it actually help an organization improve the reliability of their assets?

The answer is a resounding No.

ᐅ Play Episode

by Fred Schenkelberg 4 Comments

Please log in to view this content

by Fred Schenkelberg Leave a Comment

You may already know my position on MTBF.

If not, do not use MTBF at all, ever, in any form. So what should we use instead?

I suggest using reliability, the probability of success over a specific duration.

Let’s discuss what will work for you.

[Read more…]by Fred Schenkelberg Leave a Comment

You may already know my position on MTBF.

If not, do not use MTBF at all, ever, in any form. So what should we use instead?

I suggest using reliability, the probability of success over a specific duration.

Let’s discuss what will work for you.

by Fred Schenkelberg 10 Comments

As with other point estimates, we often want to calculate the confidence interval about the estimate. The intent is to determine the range of reasonable values for the true and unknown population parameter. For MTBF, this no different.

Here’s Fred on a Dare to Know podcast episode talking about the book and blogging about the issues and solutions concerning MTBF. You can learn more about Fred at his bio.

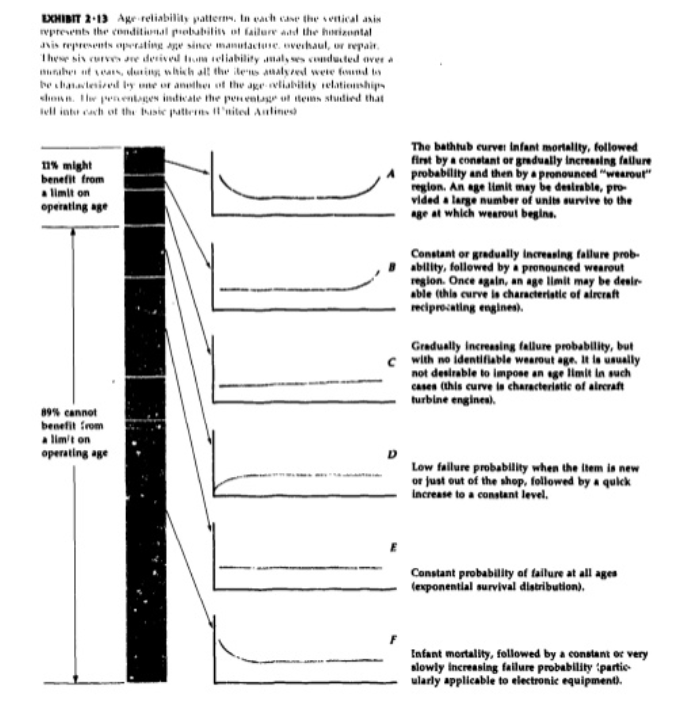

I find the world of maintenance a very odd place to find MTBF. While it is possible, that a set of equipment or a machine may actually have a constant failure rate it is the exception rather than all that common. Assuming a constant failure rate doesn’t make it so. [Read more…]

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.