The golden rule for lubricant storage is keeping the lubricant “clean, cool and dry”. Let’s discuss 3 ways to improve your lubricant storage.

What are some best practices for lubricant storage at your plant?

[Read more…]

Your Reliability Engineering Professional Development Site

by Robert Kalwarowsky Leave a Comment

The golden rule for lubricant storage is keeping the lubricant “clean, cool and dry”. Let’s discuss 3 ways to improve your lubricant storage.

What are some best practices for lubricant storage at your plant?

[Read more…]

by George Williams Leave a Comment

We review the purpose of and how to use the Notification or Service Request applications of your CMMS [Read more…]

by Perry Parendo Leave a Comment

In Experimental Design, users will at times suggest use of a 2×2 matrix. This is not a practical approach for all but the rarest of occasions. Worse yet, some will teach the 2×2 matrix because it is simple. This misleads users that it is a reasonable option. This video explains the reasons why this design should never be used during phase 1 testing. [Read more…]

by Carl S. Carlson Leave a Comment

“However beautiful the strategy, you should occasionally look at the results.”

Winston Churchill

The Oxford English dictionary defines “strategy” as “a plan of action or policy designed to achieve a major or overall aim.”

Reference the article Understanding FMEA Severity Risk – Part 1 which discusses how Severity is defined and applied in FMEA.

by Greg Hutchins Leave a Comment

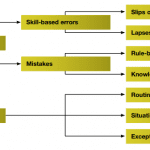

In project management we can’t always be in control of the environment around us. We can only forecast rather than predict risk and despite our ‘reasonable’ or even ‘best’ efforts to mitigate risk; shit happens and emergencies ensue! It’s not just physical emergencies but also those related to time and cost; overbudget or late projects can create an emergency for stakeholders. Perhaps it’s because we tend to look at the ‘big risks’ or the ‘top ten’ after some semiquantitative assessment but then fail to consider that risks can change with time as more information becomes available. Or, maybe it is because only those risks that can be clearly defined and are ‘likely’ are communicated to the eyes and ears on the ground. Those low probability, high impact risks can tend to slip under any risk radar.

Then there is the matter of ‘optimism bias’ and a belief that ‘nothing can go wrong’ or that ‘risk only happens to other people’. Or perhaps, it’s just a matter of management not appreciating what is going on and ‘taking their eye off the ball’. [Read more…]

by Robert Kalwarowsky Leave a Comment

A few weeks ago, I wrote about my thought processes for choosing an oil sampling location. To continue on the lubrication theme, I wanted to give you a few ideas for contamination control. Next week, I’ll take on lubricant storage. [Read more…]

by George Williams Leave a Comment

CMMS Work Order Priorities explained. [Read more…]

by Nancy Regan Leave a Comment

Watch how I made the same mistake with my shoes…and how I could have used RCM to help me! [Read more…]

by Perry Parendo Leave a Comment

When using tools such as DOE and Monte Carlo analysis, it is important to understand the capabilities of the input variables. This can lead to robust design. However, many do not ask the right questions and are surprised with less than desired performance. [Read more…]

by Greg Hutchins Leave a Comment

In another article, I discussed the results of the risk survey conducted annually by the World Economic Forum. The survey respondents are considered the economic elite. The responses provide an indication of the concerns of the movers and shakers of business. Consequently, the questions asked, and the risk concerns expressed are more policy oriented. [Read more…]

Let’s agree that the EAM Data is our organizations’ “Augean Stables”. And, we the Maintenance & Reliability professionals are “the Hercules”. It’s dirty, smelly & massive. But it is only we who can dare to cleanse it. We are the Hercules of today’s organizations. [Read more…]

by Robert Kalwarowsky Leave a Comment

I created and posted this meme a few weeks ago and it went viral through the LinkedIn reliability community. It was a tongue-in-cheek look at the vicious circle that keeps most plants in a fire-fighting mode. One of the people who shared the post asked ‘what comes first the chicken or the egg?’ In our case, reliability work comes first. [Read more…]

by Bryan Christiansen Leave a Comment

Equipment is described as reliable when it functions as designed without failure. Admittedly, equipment failure of any kind is quite inconvenient especially in fast-paced environments like the manufacturing sector. However, the consequences of failure – if it were to occur – go just beyond the usual inconveniences of unplanned downtime, lost productivity, lost revenue, etc. All these are bad enough, but should equipment failure cause injury or fatality, recovering from the consequences could become an uphill task.

by George Williams Leave a Comment

Basic overview of how long description text is managed in most CMMS systems. Tips on why you should avoid using the long description to store valuable information. [Read more…]

by Nancy Regan Leave a Comment

Oh, why oh why didn’t I employ the “Essence” of RCM when I packed for my keynote speech? Watch how I “suffered” because I didn’t! [Read more…]

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.