Article by Peter Brown

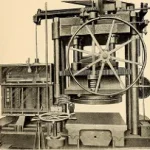

The data gathered from operating condition inspections and performance monitoring trends will increasingly appear alongside process plant performance data and be used to assign maintenance priorities and maximise plant uptime and equipment reliability.

Measuring machinery health by performance monitoring has the potential to give warning of a developing failure through the changing levels of a suitable parameter being measured, thereby indicating a change in condition of a component, machine or system.Keywords: machinery performance monitoring, machine condition assessment, equipment health monitoring

[Read more…]

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.