While working at HP as a failure analysis engineer, I was asked to join a new R&D project that needed a reliability engineer. My background was in Physics with little experience in reliability other than knowing that failures occur because reliability goals were not met. At HP, reliability engineers were integrated on each HP project by rotating many disciplines of engineering from various parts of the organization. [Read more…]

on Product Reliability

A listing in reverse chronological order of articles by:

- Kirk Grey — Accelerated Reliability series

- Les Warrington — Achieving the Benefits of Reliability series

- Adam Bahret — Apex Ridge series

- Michael Pfeifer — Metals Engineering and Product Reliability series

- Fred Schenkelberg — Musings on Reliability and Maintenance series

- Arthur Hart — Reliability Engineering Insights series

- Chris Jackson — Reliability in Emerging Technology series

Building on a Good Reliability Goal

If we set a product reliability goal of 99% reliable over two years in the requirements document, what are we supposed to do tomorrow? On the other hand, if our goal is to write 1,000 pages for the next great novel by the end of the year and we have no pages written so far, well, we should write a page or two tomorrow.

A good goal provides a vision, a measurable milestone, a target. What it lacks is what we do from now till achieving that goal. If the goal is 1,000 pages in 365 days, we may want to set up a process to write at least 3 pages per day.

So, given a reliability goal, what do we do tomorrow, next week, and each week between now and when the goal is due?

A Good Reliability Goal

In previous work, I’ve written about setting reliability goals, connecting the goal to customer expectations, technical capability, and business needs. Plus, have written about the four (five) parts of a complete goal, including Function(s), Environment, Duration, and Probability (and all four continue to get more difficult as customers expect more).

A well-stated reliability goal provides direction and a measurable target for the entire team. It provides a basis to compare progress and to help frame “is the design reliable enough yet” discussions.

This is all well and good, yet is it enough? [Read more…]

3 Ways to Improve Your Reliability Thinking

I often joke that being a reliability engineer makes it difficult to get on an airplane. Yet air travel is by far the safest method of transportation. Maybe I just think about failure too much.

When a project manager views the day’s tasks, she sees timelines, connections, dependencies. When a marketing manager views a product idea, she sees benefits, sales channels, and profits. When a reliability engineer views a prototype, she sees the many ways it can fail.

Underlying how we view the world includes our assumptions, reasoning, and experience. We understand the world around us via the set of filters we use. We form conclusions and make decisions much the same way. Quickly and mostly automatically. [Read more…]

Data Analysis and Questions to Answer

One of my standing searches revealed an article that has shows a nice example of reliability data analysis. The author analyzed the time-to-violent-death of Roman emperors. The article is interesting in a historical sense plus illustrates a few key points for any life data analysis.

The article, “Statistical reliability analysis for the most dangerous occupation: Roman Emperor” by Joseph Homer Saleh takes a look at the 69 Roman emperors and 62% of them that suffered a violent death. The idea of the study was to determine if there is some pattern to the deaths and if the analysis would reveal any insights for those studying the era of the Roman emperors. [Read more…]

Switzerland Style Attention

I’m just back from a week long trip to Switzerland. I was there developing a new Failure Mode Effects Analysis (FMEA) course for the “R is 4 Reliability” education series. If you have ever been to Switzerland you found that there are several things that are striking about this place. The natural beauty is unparalleled. Just about every view from every angle is of a beautiful snow capped mountain that has a lake or stream connected at its base. It’s never got old to look up and be viewing a real life postcard.

Second Session of HALT Seminar

Second Session!!!

“The Perfect Reliability Program Plan”

We held the New England HALT Seminar this past week. It’s a little fun thing we like to put on every so often here in Boston. We do a few sessions where we talk about Reliability topics, we then play around with the HALT chambers and break a few things. It was great having sponsorship from Espec/Qualmark, and Air Liquide this year. In past years it has just been me doing a few 30 minute sessions (one man show). But this year we had four speakers and a diverse set of topics. Definitely our best one yet. This may grow to where we can’t do it at the lab any longer. Hopefully not, I don’t want to try and bring a HALT chamber to a conference center.

How Much Reliability Data Is Enough?

Some may argue that just enough reliability data is just the right amount. Too much may lead to confusion, too little doesn’t inform well. The reliability work we do helps others make decisions, and recent work in how humans make decisions may help us prepare and present our results effectively.

If preparing reliability data-based recommendations, consider using less information. Ed O’Brien and Nadav Klein have found decision-makers tend to use much less data or information to make a decision than they think they will need.

If using data and the derived information to make a decision consider the situation carefully to know when to use a structured decision-making approach or to simply go with your gut. Daniel Kahneman and Gary Klein provide some insights and basic guidelines for decision making. [Read more…]

New England HALT Seminar

We held the New England HALT Seminar this past week. It’s a little fun thing we like to put on every so often here in Boston. We do a few sessions where we talk about Reliability topics, we then play around with the HALT chambers and break a few things. It was great having sponsorship from Espec/Qualmark, and Air Liquide this year. In past years it has just been me doing a few 30 minute sessions (one man show). But this year we had four speakers and a diverse set of topics. Definitely our best one yet. This may grow to where we can’t do it at the lab any longer. Hopefully not, I don’t want to try and bring a HALT chamber to a conference center.

5 Ways to Keep Your Audience’s Attention

I have found the best way to lose an audience is to focus on statistical derivation. While this is a fascinating subject for me, it just doesn’t seem to hold an audience’s attention.

Having something interesting and useful to say is key to maintaining an audience’s attention, yet at times how we present helps them become distracted.

So, given great content or proposal, how can you help your audience not quickly check their phone, yet again? [Read more…]

Reliability of the Little Things, and a Good Fight

My wife (Beth) and I both train and compete in Brazilian Jiu Jitsu. It’s a grappling sport like wrestling. In Jiu Jitsu your Gi (the karate looking uniform) is a big part of the sport. It’s a very heavy fabric with very specific features that are inspected before each match. Many moves involve the GI, especially the jacket. I have wrapped my sleeve around someones neck for a choke, You can grab the end of both of the opponents sleeves and dig your feed into their elbows to lock up their arms and throw them, you can use an opponent’s own lapel and wrap it around their neck for a submission or simply to roll them any way you wish.

The Porsche Adventure Continues

It’s been a few years since I have had a Porsche 911 in the stable. It seemed like the right time since were down to only two  sports cars in addition to the daily drivers. I think five cars is the bare minimum these days. “It’s only a problem if you want to stop but can’t.” I don’t want to. There are some less free spirited individuals in the house who have expressed differing opinions.

sports cars in addition to the daily drivers. I think five cars is the bare minimum these days. “It’s only a problem if you want to stop but can’t.” I don’t want to. There are some less free spirited individuals in the house who have expressed differing opinions.

My Personal Indiana Jones

I was recently in New York City for work. I stopped by to see a friend in the area. He said “I have something interesting to show you.” I was pretty excited because when Mark says “I have something interesting to show you.” you know it is going to be good. He’s a writer and his passion is finding strange and interesting things. My personal Indiana Jones. Many days he wakes up and just gives himself some adventure assignment and the goes searching for it.

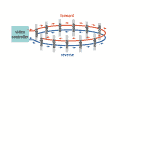

Dual-Ring Network Reliability

In the article Calculating Network Reliability the lack of published analytical solution for dual-ring network reliability was highlighted. This article provides a neat solution and further challenges readers to offer their proof or prior publication reference. The solution and the author’s general proof will be presented at RAMS 2020.

Passion to Optimize

If you recall I went on a slightly crazy adventure up to the edge of the article circle with my adventure buddy, my daughter Natalie, 11. We almost froze to death on a mountain just to see the Northern Lights (story here). But we also did something we both have always wanted to do and knew would be epic, a dog sled ride. The first thing I have to say about it is holy crap those dogs are fast. It felt like you could blow the doors off a snowmobile if you came across one.

Doing Nothing is Stressful

I was recently giving a presentation for IEEE at MIT Lincoln Labs here in the Boston area. The topic was one of my favorites, my new playground, Use Case 7 ! The crowd loved the idea of expanding how we access use cases and came up with great examples. and experiences, of their own. They found many areas in their work where the Use Case 7 exercise may yield some interesting insight.

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.