A Simple Q&A Can Reap Improved Performance in Any Activity in Maintenance.

A failure has just occurred on a critical asset in your facility. The result was 2 hours of lost production, but it could have been worse. The last time that the equipment failure occurred it took 5 hours to repair. Why was the failure repaired in less than half the time than the previous occurrence? How can we ensure that we learn from this failure and the team’s performance to improve the plant performance?

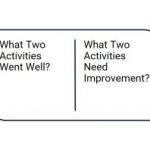

I remember reading about a simple philosophy quite a few years ago (although I can’t remember who stated it, so I apologize that I cannot provide a reference), about a simple analysis that can be applied to any maintenance activity to improve performance. This analysis is call the 2 Up / 2 Down analysis.

The 2 Up / 2 Down analysis is quite simple and involves asking two questions.

[Read more…]

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.