Risk and Reliability Lenses

Abstract

Greg and Fred discuss risk and reliability lenses for solving today’s dynamic problems.

ᐅ Play Episode

Your Reliability Engineering Professional Development Site

by Greg Hutchins Leave a Comment

Greg and Fred discuss risk and reliability lenses for solving today’s dynamic problems.

ᐅ Play Episode

by Michael Pfeifer, Ph.D., P.E. Leave a Comment

See this blog post on residual stress to learn more about residual stress

See this blog post on the five concepts to learn more.

by Greg Hutchins Leave a Comment

Risk-based auditing (RBA) is all about risk management. Risk-based auditing is simply risk transfer from the auditee to the auditor.

In today’s uncertain world, the lens for most, if not all, problem-solving and decision-making is risk. Risk-based auditing is a must-have tool for all quality and reliability professionals. ALL ISO management systems require RBA, whether 1st, 2nd, or 3rd party audits. [Read more…]

Looking at the role of waste as it affects profit, other ways to reduce cost and some of the consequences are discussed.

I reference plastic injection molding in the discussion. In case you are not familiar with the process, here’s a link to a good overview video on YouTube: engineerguy Plastic Injection Molding

All episodes and episode notes are at Way of the Quality Warrior website

You can also contact the host Keith Fong there or on LinkedIn Keith Fong on LinkedIn

by Christopher Jackson Leave a Comment

Chris and Fred discuss some of the things we have learned in the world of reliability directly due to World War II. Not many people know that around one third of today’s medical vaccines were developed out of necessity from World War II … and something similar happened when it came to making things reliable.

ᐅ Play Episode

by Christopher Jackson Leave a Comment

Chris and Fred discuss what it means to ‘assume’ something. We assume things all the time in our daily lives. We would never get anything done if we didn’t rely on quick ‘guesses’ about the world around us. But then there are those ‘assumptions’ that get us in trouble. So what’s the difference?

ᐅ Play Episode

by Mike Konrad Leave a Comment

On this episode, I have no guests as this is the final episode of the Reliability Matters Podcast for the 2023 season. Instead, let’s review what happened on the podcast this year.

A special thanks to my guests and listeners/viewers for making this podcast so successful.

by Greg Hutchins Leave a Comment

Greg and Fred discuss conformity assessment and what should and can you do to comply with a regulatory requirement.

ᐅ Play Episode

by Greg Hutchins Leave a Comment

Greg and Fred discuss how to improve your ability to get the right information to solve the right problems.

ᐅ Play Episode

by Michael Pfeifer, Ph.D., P.E. Leave a Comment

See this blog post on the five concepts to learn more.

by Christopher Jackson Leave a Comment

Chris and Fred discuss when you should do this thing called Monte Carlo simulation? … in fact … what is it?

ᐅ Play Episode

by Christopher Jackson 2 Comments

Chris and Fred discuss how we can go about estimating reliability … especially when you don’t have a lot of data, experience or other things that textbooks say you need to have to estimate reliability?

ᐅ Play Episode

by Fred Schenkelberg 3 Comments

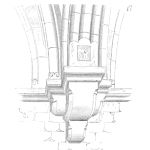

I recently received a question about the artwork found at Accendo Reliability. “Why castles?” So, I provided an answer and thought I would share it in this webinar. Also, let’s talk about how and why Accendo Reliability got started and how it’s been doing over the past ten years. [Read more…]

by Mike Konrad Leave a Comment

We are all aware of the damage electrostatic discharge can wreak on components and electronic products. We mitigate ESD damage through various forms of monitoring. We wear wrist and heel straps, stand on ESD-safe flooring, utilize ESD work stations, and more. We even have ESD testing locations that will test a human standing on a specialized testing station. But what happens the moment that person steps off the tester?

My guests today are Dr. Daan Stevenson and Dr. Jonathan Tapson of IONA Tech, a manufacturer of a novel wearable ESD monitoring device that provides constant real time ESD monitoring.

Normally, I don’t talk about specific products on the show. We usually limit our conversations to best practices. This is a little bit of an exception to my normal rule. From time to time, a product is introduced that is so novel, it’s worthy of a conversation. And that’s the case here.

Dr. Daan Stevenson is the Chief Executive Officer of IONA Tech. Daan has a background in mechanical and aerospace engineering. During his doctoral research, he studied the high voltage charging of spacecraft, which are electrical capacitors in the same way that the human body is. While working to design an automated ground station for UAVs, he frequently damaged electrical components from electrostatic shocks. This motivated the creation of IONA Tech, with the goal of advancing technology in ESD mitigation.

My other guest is Dr. Jonathan Tapson, Chief Technology Officer of IONA Tech. Jonathan was Professor of Electrical Engineering at Western Sydney University before moving to Telluride Colorado in 2016. He spent his early career conducting sensor and instrumentation research, with a strong industrial focus. During this time he spun out three companies from his research, all of which are successful today. His specialties include low-noise circuits and systems design, mechatronic design and the integration of machine learning into real-time systems.

Contact Information:

Daan Stevenson

daan@iona.tech

Jonathan Tapson

jon@iona.tech

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.